|

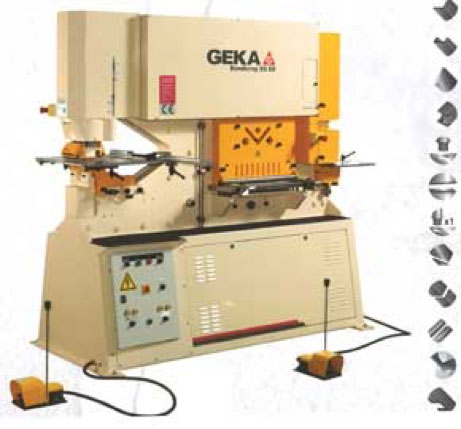

Geka Ironworkers process angles, flat bar and steel profiles used in the construction of prefab metal structures; towers for high-voltage power lines and power stations; telecommunication towers; and other divers industrial metalworking applications.

|

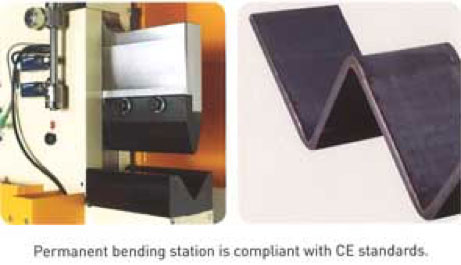

Bendicrop

Universal Punching and Shearing Machines with Permanent Bending Station.

|

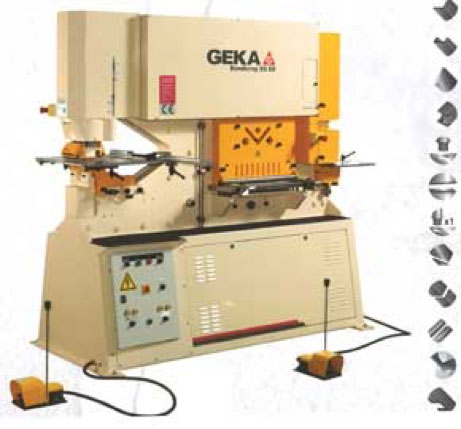

Hydracrop

Two-Cylinder Punching and Shearing Machines.

Where production requires twin operator machines, higher speeds or greater capacity Geka provides the solution with the Hydracrop range with five work stations.

|

|

Minicrop

One Cylinder Universal Ironworker with Four Stations

Optional Blades for shearing UPN and IPN section up to 100 mm:

|

Multicrop

Four Stations Plus a Shearing Angle Section Iron

The Multicrop Includes Standard Shear Blades:

< <

|

|

Common Features to Minicrop and Multicrop:

|

|

Microcrop

Ironworker One Cylinder Punching Machine with Three Work Stations

|

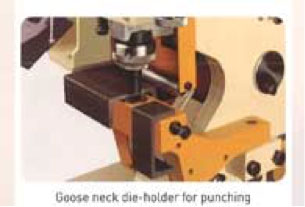

Puma

Puma Hydraulic Punching Machines

|

|

Semi-Paxy

Bringing the newest CNC automation and positioning technology to punching of steel

|

Auto Gauge at Punch - Auto Feeder at Shear:

|

CNC Feeder for Punch

|

TRIPLE-PUNCHING HEAD

- Three on-demand, programmable punches

- Diameters up to 1-9/16”

- Punching is accomplished by means of forcible strokes or blows

- Excellent for operations requiring identical perforations with varying diameters

|

|

|

<

<