|

Setting the Standard for American-Made Metal Fabrication Equipment |

||||||||

Press Brakes |

||||||||

|

One of the true advantages of the Standard drive system is our ability to provide full tonnage across the bed and ram and not create excessive side loads. This is accomplished because all forces are vertical above the ram centerline and are fully contained within the extremely heavy duty "box" structure. This structure houses the drive system and our impressive 3 point ram guidance/gibbing system. The front to back forces are controlled with our precision machined set of "ways" combined with extremely heavy duty slides. These ways and guides are located both front and back of the ram and at both ends of the ram. The third set of gibbs is our innovative and very formidable center thrust gibb. This impressive gibbing system is self-aligning and requires no operator action during ram alignment. All three sets of gibbs control the front to back and left to right forces providing the precision +, -.001" ram repeatability.

OUR BRAKES ARE SPECIFICALLY DESIGNED FOR THE FOLLOWING APPLICATIONS: FULL LENGTH BENDS - where full tonnage across the bed is required for the truest bends OFF-CENTER LOADING - especially when needing substantial tonnage near the ends of the brake CENTER LOADING - when any amount of tonnage is required in the center or anywhere across the bed MULTIPLE DIE SET-UPS - across the bed that require the same or varying amounts of tonnage PUNCHING APPLICATIONS - great for punching alone or combined with forming SHORT PIECE WORK - with some of the fastest ram speeds, you small piece work is done quickly easy with precision

|

||||||||

Shears |

||||||||

|

||||||||

|

||||||||

|

||||||||

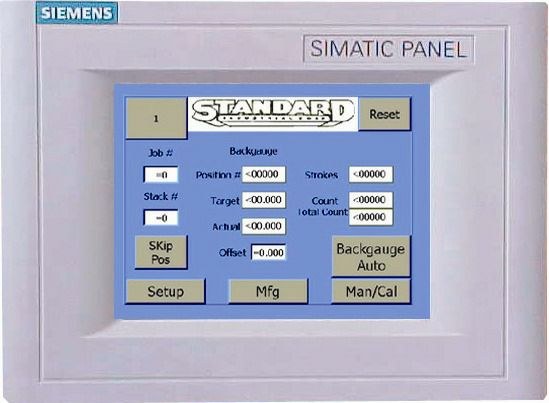

Siemens CNC control

|

||||||||

|

||||||||

36" or 48" Travel EXTREMELY Heavy Duty Backgauge

|

||||||||

|

No other backgauge comes close to the rigidity coupled with the brute strength of the Standard Industrial shear backgauge. Perfectly built for precision and outright ability to take abuse.

|

||||||||

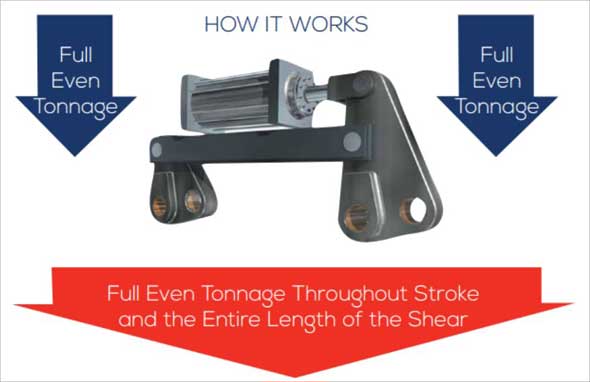

Single Horizontal Cylinder:

|

||||||||

|

The single cylinder horizontal cylinder creates full tonnage via the massive bellcrank linkage system. Powered by just one cylinder, the bellcrank linkage supplies full tonnage the entire length of the shear. On each end of the shear ram is an incredibly heavy-duty and precision-machined tapered gibb system. This gibb system controls all front to back and left to right forces to provide the most precision cut available. With only one cylinder you do not have to worry about "balancing" two cylinders and creating un-even tonnage and distortion in the cut. One cylinder creates full tonnage the entire cut instead of multiple cylinders creating various amounts of force. |

||||||||

Presses |

||||||||

|

||||||||